Lean to Six Sigma: process improvement methodologies explained

Georgina Guthrie

December 26, 2021

Processes get a bad rep. Even the word itself conjures up images of paperwork, spreadsheets, and overzealous managers breathing down your neck. And to some extent, it’s totally fair. Often, business processes consume more time than the work itself requires. But those are the bad ones, and we’re pleased to say it doesn’t need to be this way.

We’re going to quickly run through the best process improvement methodologies and give you the lowdown on how they can help you strengthen your business.

What are process improvement methodologies?

Disorganization is a dragon that every business has to slay. Teams don’t function well when every person uses different resources, makes independent decisions, and relies on their own methods. You might make some progress with this chaotic approach. However, you’ll run into one obstacle after the next when you try to measure performance or get consistently good results.

The better option is to develop proven strategies that work for your team and then perfect them to improve output and efficiency.

Process improvement methodologies are techniques that make your business operations run as smoothly as possible. This could include collaborative tasks between teams, technical development, or physical production processes. The payoff? Organizations that conduct regular analysis are more likely to:

- Identify broken processes

- Find and fix bottlenecks

- Motivate and retain employees

- Build stronger teams that share their best ideas

Process improvement helps to reduce delays, eliminate redundancies, and boost productivity in crucial business operations. By outlining your business goals, you can identify areas for continuous improvement and get better at managing time, staff, and resources.

Six Sigma

Born in the ’80s, Six Sigma is all about continually collecting data to eliminate defects and improve processes. The ultimate goal? Reduce errors, reduce cycle times, and increase customer satisfaction.

Six Sigma has two sub-methodologies: DMAIC for improving existing processes and DMADV for creating new ones.

DMAIC

DMAIC is an acronym for Define, Measure, Analyze, Improve, and Control.

It’s a five-step process designed to rejuvenate existing methods that are underperforming. It helps you understand your company’s stumbling blocks and how to fix them long-term.

Who’s it for?

Everyone, especially teams that want to cut time and cost on major projects.

DMADV

Also known as Design for Six Sigma, it stands for Design, Measure, Analyze, Design, Verify. This is a similar methodology, but it involves improving a process that doesn’t exist yet.

DMADV can create processes for a brand new project or replace existing, ineffective methods. The role of DMADV is to help you build a new process that works.

Who’s it for?

Again, it’s for everyone, especially teams looking to reduce errors, save time, and improve customer satisfaction.

Helpful Six Sigma diagrams

Diagramming is a useful tool for Six Sigma process improvement. Creating a visual allows you to look closely at the phases of a process and figure out where problems develop. Here are popular examples of Six Sigma diagrams.

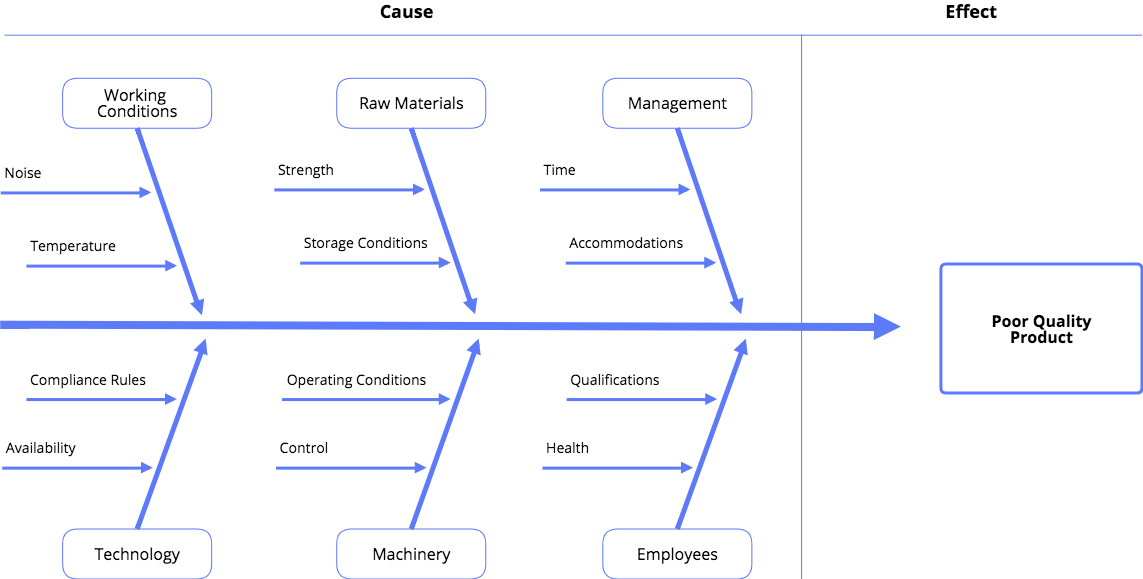

Cause and effect analysis (AKA Fishbone Diagram, AKA Ishikawa Diagram)

Use this approach to work out the root cause of a problem. You’ll see the problem or defect at the front with the categories branching from it. Typically, the categories include personnel, materials, measurements, machines, methods, and environments. However, feel free to customize the diagram to fit your business needs.

Who’s it for?

Everyone and every industry.

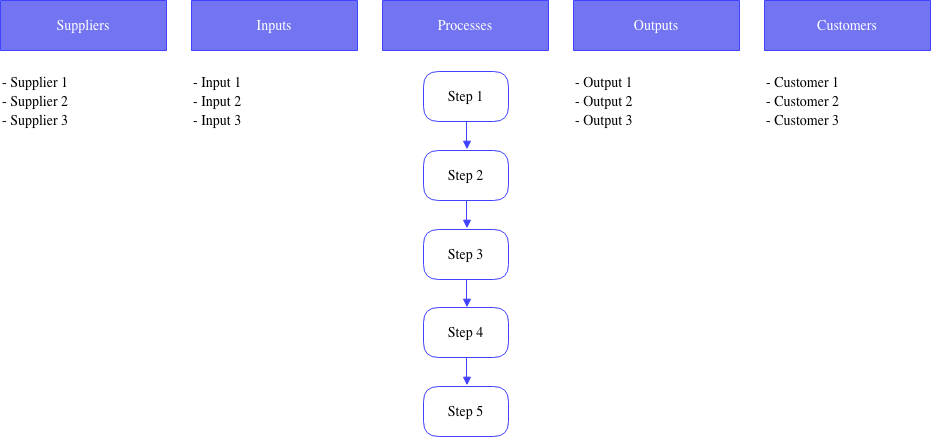

SIPOC Analysis

This diagram is commonly used in manufacturing and stands for Supplier, Input, Process, Output, and Customer. A SIPOC analysis can identify each element of a process improvement project before it kicks off. This diagram is most valuable during the ‘measure’ phase of the DMAIC methodology.

A SIPOC diagram consists of a simple table with five columns for each of your SIPOC processes.

- Supplier: the people, departments, or organizations that provide the raw material or input

- Input: the equipment or information that you need to carry out a process

- Process: the steps involved

- Output: a list of the products or services going to the client

- Customer: a list of recipients who will receive your product or service

Who’s it for?

Manufacturers who want to identify all the relevant components of a process improvement project and define projects that haven’t been fully scoped yet.

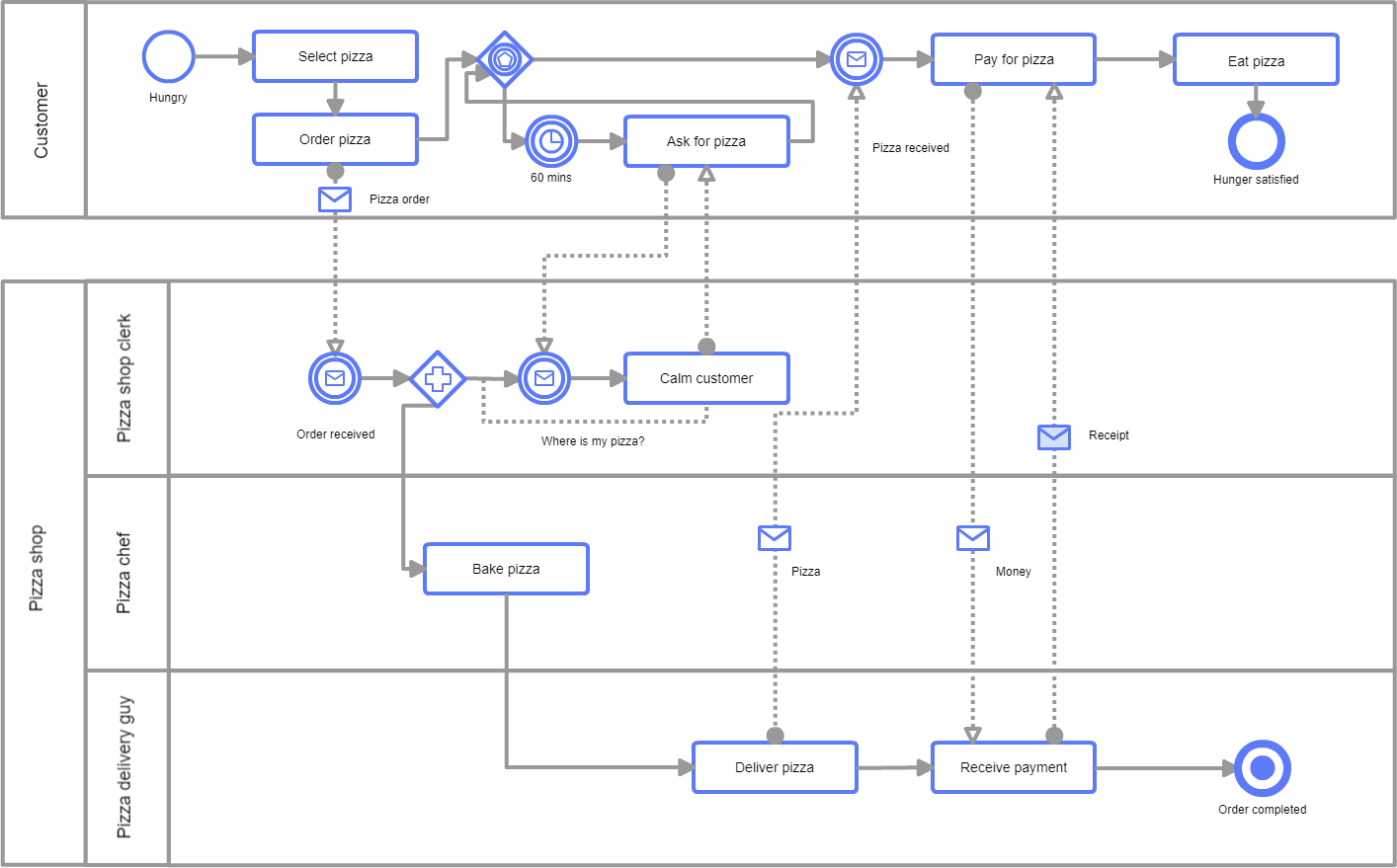

Process Mapping

Business Process Model and Notation (BPMN), or process maps, are graphic displays of all the steps and operations that constitute the entire process. So while the other diagrams above help you understand a specific part of the process, this is a detailed overview of the whole thing.

Who’s it for?

Everyone and all industries. It’s helpful in understanding how entire processes work and identifying areas that could improve.

Lean Manufacturing

Don’t be put off by the title. Lean process improvement methodologies work for any industry, not just manufacturing. Lean is all about minimizing waste until you have only the essential value-adding components left.

What’s the difference between Lean Manufacturing and Six Sigma? While both essentially have the same objective — to improve processes — the former is all about improving efficiency by eliminating unnecessary steps. The latter is about improving quality by reducing defects.

There are eight types of waste Lean Manufacturing seeks to eliminate:

- Overproduction: too many materials ahead of demand

- Overprocessing: extra work due to poor tools

- Waiting: interruptions, downtime, or inactivity

- Non-utilized skills: not fully utilizing employee knowledge or talent

- Transportation: poor product logistics

- Motion: unnecessary movement of people or equipment

- Inventory: having a larger surplus than needed for the task

- Defects: time wasted checking for issues or defects

Now that we understand what to look for, let’s examine three different ways to combat these issues.

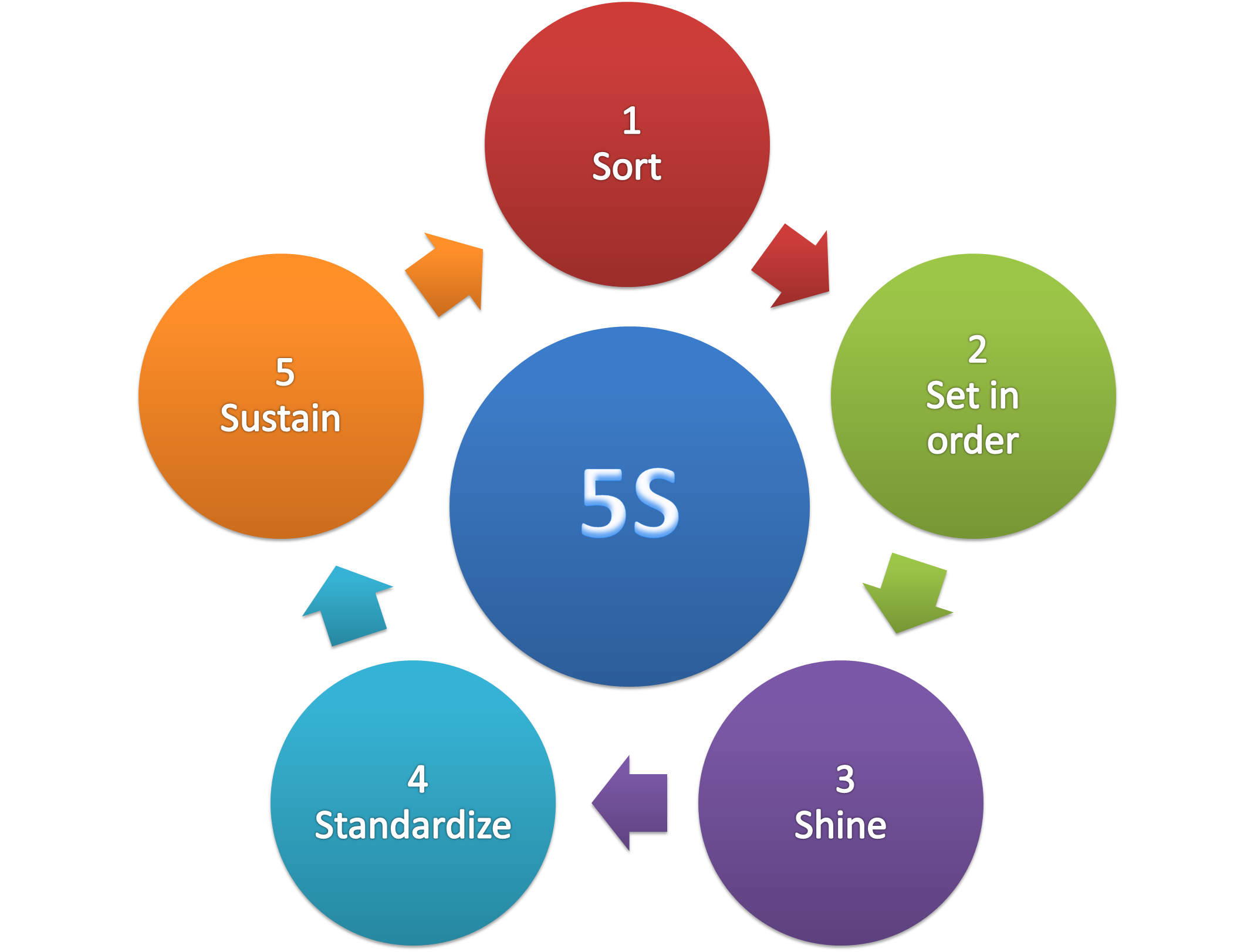

5S

5S is a workplace methodology with five tenets — Sort, Set in order, Shine, Standardize, and Sustain. The purpose of 5S is to promote workspace organization and efficiency.

You can create a 5S diagram in the form of a circle that’s split into segments or use a linear format. Split the segments into five sections with a short description underneath each one, so everyone knows what they represent.

- Sort: work out what’s essential and what’s not

- Set in order: organize everything in your workspace

- Shine: clean your space and equipment ‘till it’s sparkling

- Standardize: create a system that makes this process easy for everyone to follow

- Sustain: make this process easy so that it can become a habit

Who’s it for?

Everyone and every industry. 5s analysis is straightforward and requires no training. It’s a great method to increase team efficiency, promote safety, and standardize ways of working.

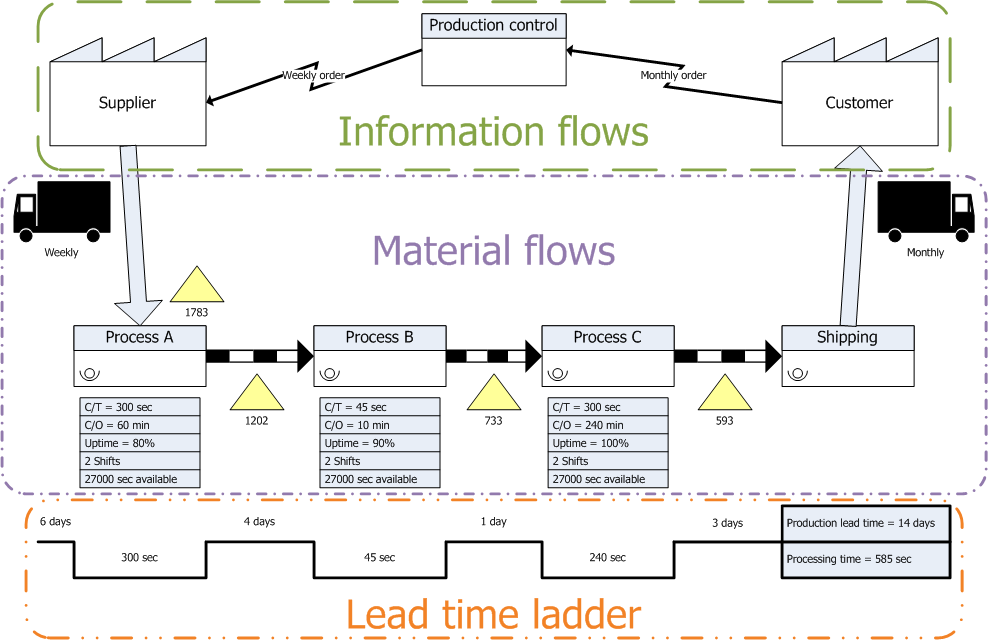

Value Stream Mapping

Value maps document the flow of tasks, information, and materials that go into a project. The aim is to sort activities that add value from those that don’t, so you can see which should be trimmed off the process.

Who’s it for

It’s useful for everyone but favored by manufacturers looking to identify waste within processes and gain insight into process flows. It’s also helpful for goal-setting and prioritizing.

Total Quality Management

Total Quality Management (TQM) is essentially an organization-wide process where every department and employee works towards improving their supply of products or services.

TQM is the most subjective of all the methodologies because it varies so much from company to company. But some hallmarks of this process include:

- Customers determine the level of quality

- All employees work towards common goals

- Quality increases over time due to continual and systematic measurement, analysis, and improvement

- Managers define the required goals, manage performance, and continually look for new ways to be more effective

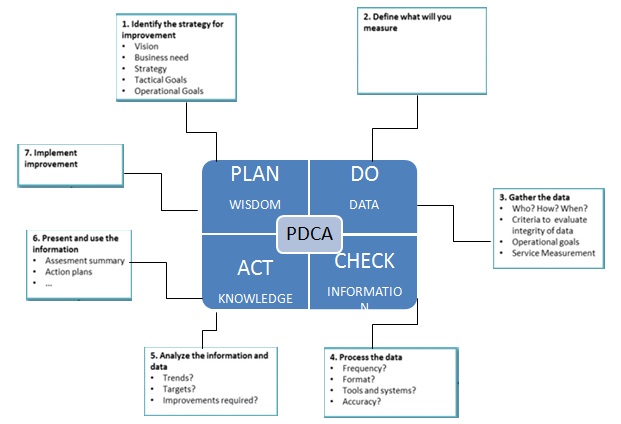

As with the other processes, having a good diagram in place will help you visualize your data and organize your thoughts. There’s no formal way to document quality, but Ishikawa / fishbone diagrams (mentioned above), check sheets, and flowcharts are popular options. You can also use a PDCA (Plan, Do, Check, Act) cycle, a diagram used to track continual improvement.

- Plan: Outline your objective, the steps needed to complete it, and methods of measuring performance.

- Do: Carry out the above.

- Check: Measure your plan’s success.

- Act: Make the successes the new process.

Who’s it for?

Because of its flexible definition, TQM can be adapted for all industries. It encourages participation from every member of the organization, from the shop floor to the biggest of big cheeses!

Kaizen (Change for the better)

Kaizen is another type of Lean methodology that originated among Japanese businesses. While it’s the basis for other techniques, such as 5S and PDCA, Kaizen deserves its own spot on this list. Masaaki Imai, the founder of the Kaizen Institute, popularized this method as a means of continuous improvement in every aspect of life, creativity, business, production, and teamwork.

Kaizen is all about streamlining every business element, so you’re always implementing dynamic strategies. You can apply this methodology to everything from product design to company culture. Kaizen takes many forms depending on its application, but the following are common principles.

- Let it flow: Don’t hold onto ideas or resources you don’t need. Reduce waste to create more value.

- Know your goal/customer: Think about what you want to achieve and provide the best experience by focusing your efforts effectively.

- Be transparent: Rely on accurate data, not assumptions and guesses, to drive performance.

- Optimize teams: Empower your team and provide the right tools to motivate and support them.

- Follow the action/go to Gemba: Focus your presence in places where relevant action is happening.

Each of these principles is associated with specific processes for continuous improvement. But the overall message of Kaizen is to perform constant “housekeeping.”

Businesses shouldn’t stick to familiar ideas and processes simply because these are the methods they used in the past. And leaders should hold themselves to the same standards of growth and “uninterrupted change.” By fostering an endless cycle of improvement, you can get rid of complacency in your organization.

Who’s it for?

Kaizen translates to “change for the better.” As a broad methodology, it’s meant to encompass every business element. Different branches of Kaizen are easy to develop and implement for specific departments or business goals.

Final thoughts

Whichever combination of process improvement methodologies you choose, make sure you have all the tools in place to set off on the right foot.

Working with a good project management tool is never a bad idea. Not only is it ideal for teamwork, but PM tools allow you to measure the results of process improvement methodologies. Then, you can standardize processes that work and figure out how to fix methods that need more improvement.

And don’t forget to invest in a cloud-based diagramming tool that lets you professionally visualize and share all that data.

This post was originally published on November 20, 2018, and updated most recently on December 26, 2021.